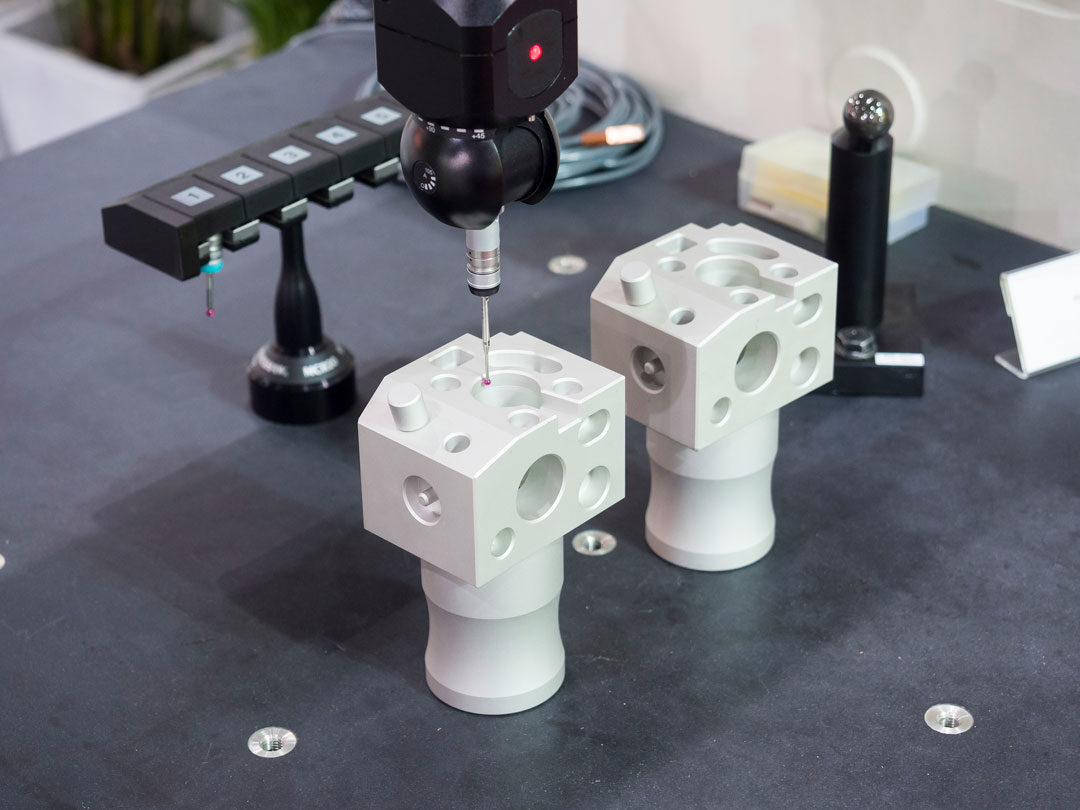

QC Lab

You can't ensure precision without a worldclass QC Lab. In all the industries we serve, quality requirements have never been higher – particularly for the tight-tolerance work we're known for. That's why, as part of our single-source, under-one-roof capabilities, Sycamore Precision has invested in one of the industry's most comprehensive quality assurance departments. We've put all the quality resources in place to ensure the complete inspection of the widest range of part types and diverse inspection criteria. Our highly trained quality technicians have access to resources that generally aren't available in-house, thus also ensuring faster throughput and greater economies than possible when inspection is outsourced. For example:

Inspection Resources:

- (1) Brown & Sharpe 7-10-7 Coordinate Measuring Machine

- (1) Brown & Sharpe B & S 7-10-7 Coordinate Measuring Machine

- (1) Brown & Sharpe Global Advantage 9-15-8 Coordinate Measuring Machine

- (1) Jones & Lamson 14" Optical Comparator with Quadra Check III

- (1) Uson Electronic Mass Flow Meter

- (1) Cincinnati Electronic Mass Flow Meter

- (6) Uson Pressure Decay Testers with burst and flow testing

- (4) Edmunds Air Gage Columns

- (2) Precision Gage Air Gage Columns

- (1) Mahr Federal Contour Measuring Station XC20

Quality Control Resources:

- Real Time SPC

- Computerized Statistical Process Control

- Surface Finish Measuring Equipment

- Complete Sets of Standard Plug, Ring and Thread Gages

- Salt Spray Testing Booth